From the ship directly to the traders

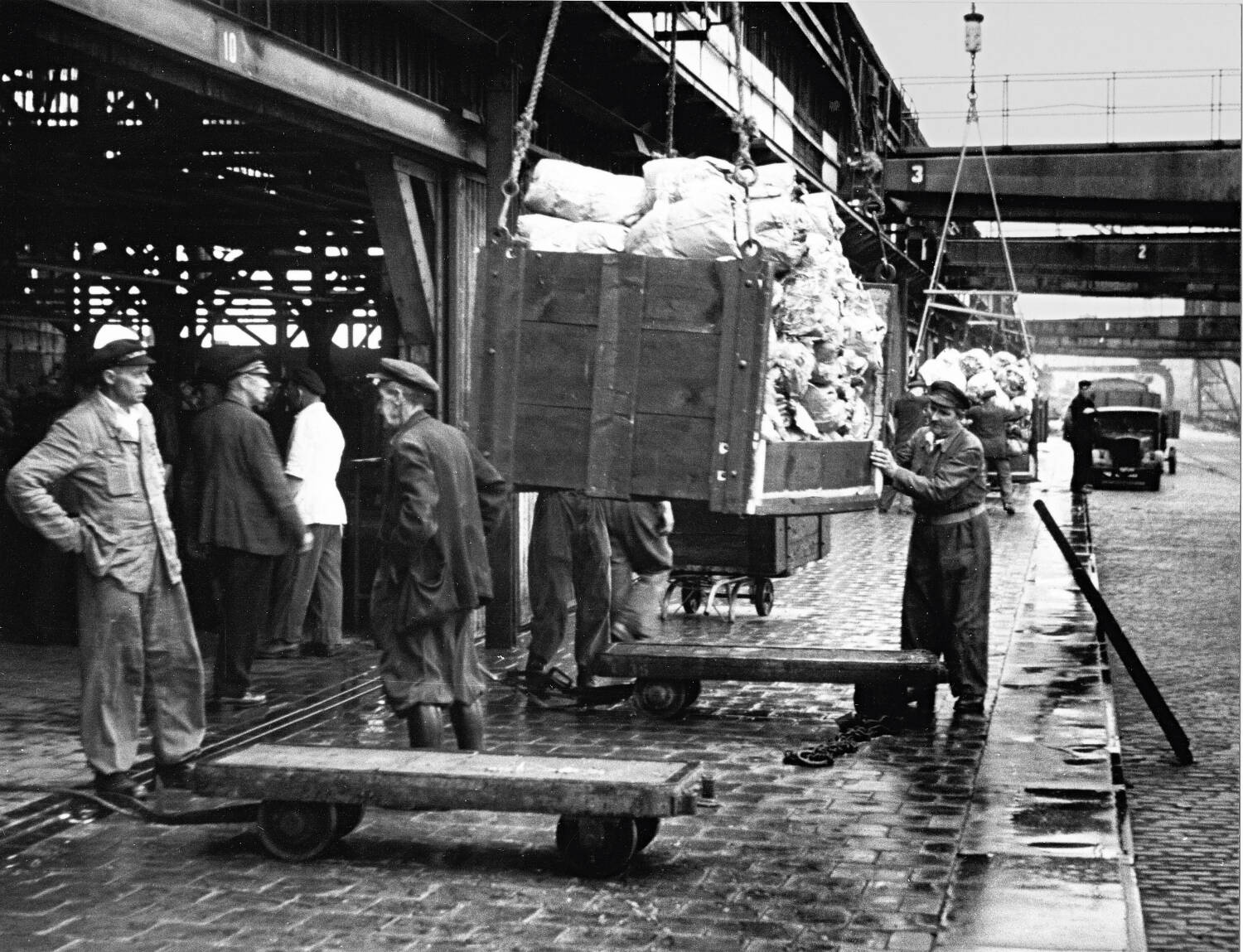

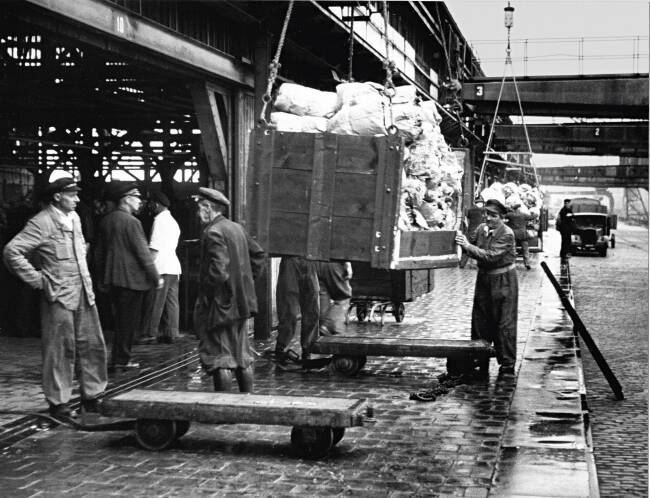

Conveyor belts run right through a fruit shed in Hamburg (1929). Workers use them to sort the banana plants that have just arrived by ship.

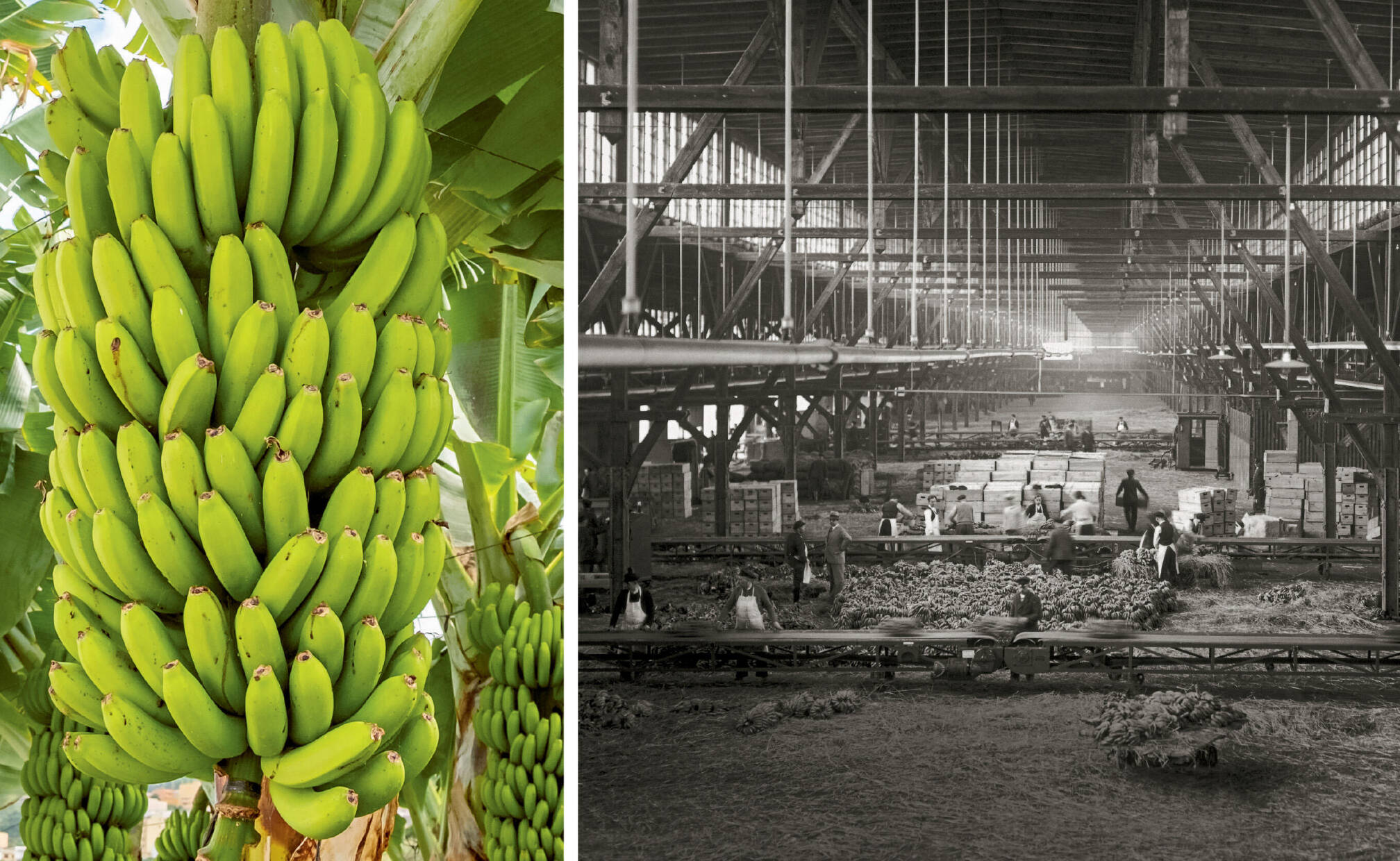

For more than 100 years, Hamburg has been one of Europe’s most important ports for importing tropical fruits such as bananas – a delicate operation where importers and wholesalers have to rely entirely on logistics companies.

The steamship Tropani, property of the Hamburg-based shipowner Rob. Sloman jr., moored in the Port of Hamburg in 1897 carrying a cargo of highly sensitive goods: “10,000 crates of citrus” as stated in the freight documents. The most popular of all the “tropical fruits” at the time had to be discharged quickly and sold as soon as possible. If this didn’t happen, a newly built state-of-the-art fruit shed was waiting to provide interim storage at Versmannkai. The double-shell shed, which was thermally insulated and heated with the aid of peat waste, was operated by the state quay administration, which later merged with HFLG to form HHLA.

At the turn of the century, Hamburg quickly rose to become one of Europe’s main fruit trading centres. This was also made possible by close cooperation with customers. When the two-storey fruit shed C was inaugurated in Magdeburg Dock in 1912 – with the press lauding it as “groundbreaking for Hamburg” – the packing and shipping rooms of the fruit consortium were located on the upper floor. Other special sheds were built, which meant that fruit – and especially apples from the USA in addition to citrus fruit from the Mediterranean region – accounted for an ever larger share of the cargo in the Port of Hamburg. By 1910, their share had tripled to 1.4 per cent of all goods handled.

The Germans get their favourite fruit via Hamburg

Despite interruptions due to the First World War, inflation and the global economic crisis, fruit imports continued to gain momentum. In 1931, the quay administration equipped shed 48 with weatherproof elevators, which transported the bananas arriving in unpacked bunches directly into the halls. By 1934, special sheds had been built for the first time for the curved yellow fruit. They were not spared the destruction of the Second World War, but were quickly rebuilt in a modernised form. They were urgently needed, not least because the banana had become a real staple. The Germans had the highest per capita consumption in the world, and they were mainly supplied via Hamburg.

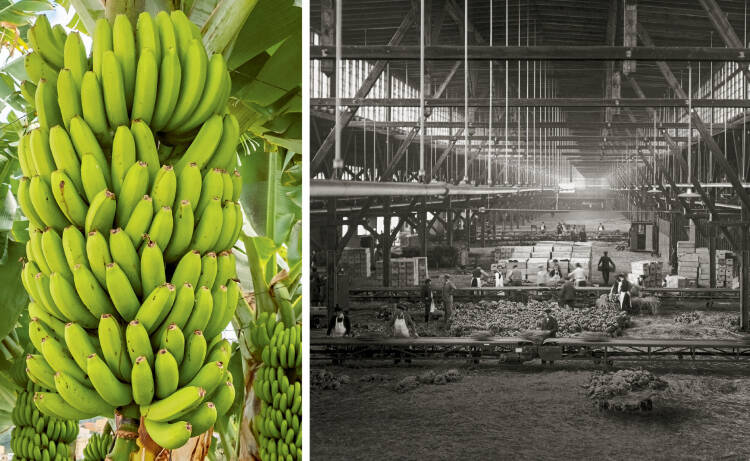

“Hiev an!” – “Hieve!”, shouted the dockers once they had readied a “load” full of banana plants for transport by truck.

By 1954, Hamburg’s fruit trade had reached a volume of 233,000 tonnes. This was more than double that of its closest competitor Rotterdam, mainly thanks to banana handling, which was approaching the half-million-tonne mark. Without standardisation and early automation, such quantities could no longer be handled at the speed needed for perishable goods.

In the mid-1970s, HHLA therefore started work on constructing a technologically pioneering fruit centre with almost twice as much cold storage space – again in line with the wishes of the fruit trade. The HHLA Frucht- und Kühl-Zentrum was inaugurated in 1978 on the site of O’Swaldkai, now HHLA’s multipurpose terminal. It boasted an area of some 720,000 m², making it the second largest handling facility in the entire port at the time.

The race for the most modern fruit logistics operation

The employees had developed the most modern banana shed in Europe, featuring a partially automated system controlled by photoelectric sensors. They also advised exporters in the producing countries and were able to convince them of the advantages of standardisation, soon enabling production to take another leap forward as a result of the palletising of the goods. Mobile cranes working in sync with the forklifts were now able to handle and store much larger quantities at once.

End-to-end cold chain: Elevators once handled reefer ships to transport banana crates directly into the cold store.

What would provisionally be the last stage in the European race for the most modern fruit logistics operation opened in 2009 at O’Swaldkai. The semi-automated refrigerated warehouse at the HHLA Frucht- und Kühl-Zentrum has four cold stores with separate temperature zones that can accommodate 8,000 pallets (400,000 boxes or 7,600 tonnes of bananas).

Chip-controlled processes, transparent at every stage

The facility also plays a key role in the increasingly important area of comprehensive quality control. Each pallet placed into storage bears a barcode that is scanned in the entrance area of the refrigerated warehouse and “married” to the RFID chip of a pallet. Every pallet movement across five levels – using continuous conveyors and storage and retrieval machines – is tracked by the software. The goods are retrieved for shipping in a chip-controlled process so that the pallet only has to be loaded onto the waiting trucks.

Fast and accurate: Instead of individual plants or crates, entire pallets are now handled and placed into storage at the HHLA Frucht- und Kühl-Zentrum. The importers check the quality of the goods in the port.

Complete traceability of the goods is guaranteed by scanning them as they arrive and leave the warehouse, which is important for creating a transparent and computer-aided transport chain in the fruit industry. Importers and wholesalers can fully rely on this logistics operation. The fruit forwarding company Ulrich Stein also plays a key role here. Using software developed in-house, the HHLA subsidiary ensures that all customs regulations are met. It also makes sure that the import licences are always up to date and that the necessary samples of goods are presented to the authorities. Everything is done with the aim of ensuring that the Germans’ favourite fruits find their way into people’s fruit baskets as quickly as possible.

Interview with Prof. Dr Jürgen Zimmerer read more

Hamburger Hafen und Logistik Aktiengesellschaft

Bei St. Annen 1

20457 Hamburg

Phone +49 40 3088-0

www.hhla.de/en

Responsible in terms of the German press law

Carolin Flemming, Head of Corporate Communications

→ Write e-mail

Photo credits

HHLA, Sebastian Engels, Aliaksandr Mazurkevich, Tibor Patacki, Thies Rätzke, Joerg Schwalfenberg, Gustav Werbeck

Editor in chief

Christian Lorenz

From the ship directly to the traders

Conveyor belts run right through a fruit shed in Hamburg (1929). Workers use them to sort the banana plants that have just arrived by ship.

For more than 100 years, Hamburg has been one of Europe’s most important ports for importing tropical fruits such as bananas – a delicate operation where importers and wholesalers have to rely entirely on logistics companies.

The steamship Tropani, property of the Hamburg-based shipowner Rob. Sloman jr., moored in the Port of Hamburg in 1897 carrying a cargo of highly sensitive goods: “10,000 crates of citrus” as stated in the freight documents. The most popular of all the “tropical fruits” at the time had to be discharged quickly and sold as soon as possible. If this didn’t happen, a newly built state-of-the-art fruit shed was waiting to provide interim storage at Versmannkai. The double-shell shed, which was thermally insulated and heated with the aid of peat waste, was operated by the state quay administration, which later merged with HFLG to form HHLA.

At the turn of the century, Hamburg quickly rose to become one of Europe’s main fruit trading centres. This was also made possible by close cooperation with customers. When the two-storey fruit shed C was inaugurated in Magdeburg Dock in 1912 – with the press lauding it as “groundbreaking for Hamburg” – the packing and shipping rooms of the fruit consortium were located on the upper floor. Other special sheds were built, which meant that fruit – and especially apples from the USA in addition to citrus fruit from the Mediterranean region – accounted for an ever larger share of the cargo in the Port of Hamburg. By 1910, their share had tripled to 1.4 per cent of all goods handled.

The Germans get their favourite fruit via Hamburg

Despite interruptions due to the First World War, inflation and the global economic crisis, fruit imports continued to gain momentum. In 1931, the quay administration equipped shed 48 with weatherproof elevators, which transported the bananas arriving in unpacked bunches directly into the halls. By 1934, special sheds had been built for the first time for the curved yellow fruit. They were not spared the destruction of the Second World War, but were quickly rebuilt in a modernised form. They were urgently needed, not least because the banana had become a real staple. The Germans had the highest per capita consumption in the world, and they were mainly supplied via Hamburg.

“Hiev an!” – “Hieve!”, shouted the dockers once they had readied a “load” full of banana plants for transport by truck.

By 1954, Hamburg’s fruit trade had reached a volume of 233,000 tonnes. This was more than double that of its closest competitor Rotterdam, mainly thanks to banana handling, which was approaching the half-million-tonne mark. Without standardisation and early automation, such quantities could no longer be handled at the speed needed for perishable goods.

In the mid-1970s, HHLA therefore started work on constructing a technologically pioneering fruit centre with almost twice as much cold storage space – again in line with the wishes of the fruit trade. The HHLA Frucht- und Kühl-Zentrum was inaugurated in 1978 on the site of O’Swaldkai, now HHLA’s multipurpose terminal. It boasted an area of some 720,000 m², making it the second largest handling facility in the entire port at the time.

The race for the most modern fruit logistics operation

The employees had developed the most modern banana shed in Europe, featuring a partially automated system controlled by photoelectric sensors. They also advised exporters in the producing countries and were able to convince them of the advantages of standardisation, soon enabling production to take another leap forward as a result of the palletising of the goods. Mobile cranes working in sync with the forklifts were now able to handle and store much larger quantities at once.

End-to-end cold chain: Elevators once handled reefer ships to transport banana crates directly into the cold store.

What would provisionally be the last stage in the European race for the most modern fruit logistics operation opened in 2009 at O’Swaldkai. The semi-automated refrigerated warehouse at the HHLA Frucht- und Kühl-Zentrum has four cold stores with separate temperature zones that can accommodate 8,000 pallets (400,000 boxes or 7,600 tonnes of bananas).

Chip-controlled processes, transparent at every stage

The facility also plays a key role in the increasingly important area of comprehensive quality control. Each pallet placed into storage bears a barcode that is scanned in the entrance area of the refrigerated warehouse and “married” to the RFID chip of a pallet. Every pallet movement across five levels – using continuous conveyors and storage and retrieval machines – is tracked by the software. The goods are retrieved for shipping in a chip-controlled process so that the pallet only has to be loaded onto the waiting trucks.

Fast and accurate: Instead of individual plants or crates, entire pallets are now handled and placed into storage at the HHLA Frucht- und Kühl-Zentrum. The importers check the quality of the goods in the port.

Complete traceability of the goods is guaranteed by scanning them as they arrive and leave the warehouse, which is important for creating a transparent and computer-aided transport chain in the fruit industry. Importers and wholesalers can fully rely on this logistics operation. The fruit forwarding company Ulrich Stein also plays a key role here. Using software developed in-house, the HHLA subsidiary ensures that all customs regulations are met. It also makes sure that the import licences are always up to date and that the necessary samples of goods are presented to the authorities. Everything is done with the aim of ensuring that the Germans’ favourite fruits find their way into people’s fruit baskets as quickly as possible.

Interview with Prof.

Dr Jürgen Zimmerer

read more

Hamburger Hafen und Logistik Aktiengesellschaft

Bei St. Annen 1

20457 Hamburg

Phone +49 40 3088-0

www.hhla.de/en

Responsible in terms of the German press law

Carolin Flemming, Head of Corporate Communications

→ Write e-mail

Editor in chief

Christian Lorenz

Photo credits

HHLA, Sebastian Engels, Aliaksandr Mazurkevich, Tibor Patacki, Thies Rätzke, Joerg Schwalfenberg, Gustav Werbeck